- Okawbow

- Ten ring

Offline

Offline - From: Southern Illinois

- Registered: 11/04/2015

- Posts: 123

The quest for the short string

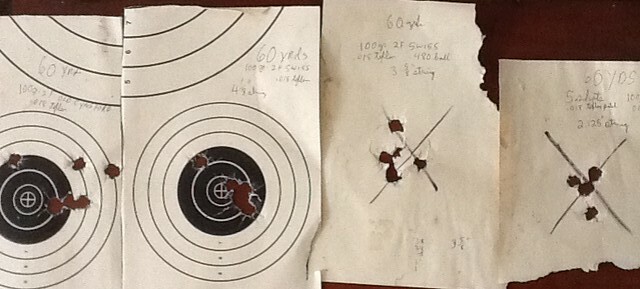

After shooting a 13 1/2" string at the Alvin York match earlier this month; I have made some changes to my gun and my load.

I changed my front sight to a hooded pin type sight, and my spotter to a white circle inside a black circle, on a bright green paper.

I re-crowned the muzzle of my barrel, by taking off about 1/8" and making a new crown on my lathe. Apparently, I ended up with the muzzle too sharp, as I was cutting patches.

I switched from denim patches lubed with balistol and water, to .018 Teflon coated patches from Minutemen. Everyone else at the York shoot, around me, was using Teflon.

I also bought some Swiss powder, as again, everyone around me was using Swiss.

I shot 4, 5 shot groups. I polished the muzzle crown between the first 2 groups, until I wasn't cutting patches as badly. The low shot on the last group was because of a blown patch. Still need to polish more.

Surprisingly, my last and best group was with Old Eynsford powder. I tried it again to see how much difference it would be from Swiss. Seems close if not better in my gun.

Next on the list is weighing powder charges and balls to get more consistent.

Getting closer! image by okawbow, on Flickr

image by okawbow, on Flickr

Last edited by Okawbow (4/17/2016 1:26 PM)

- crankshaft

- Eight ring

Offline

Offline - Registered: 2/12/2015

- Posts: 53

Re: The quest for the short string

Good write up...thanks,

slacker

- rhbrink

- Target master

Offline

Offline - From: Pleasant Hill, MO

- Registered: 7/26/2014

- Posts: 285

Re: The quest for the short string

And the Quest goes on and on and on but that part of the fun for me always seeking a little bit better group. Shave off a tenth here and shave of a tenth there and pretty soon you have a winning combination. I have been experimenting with the 2FF Olde Enysford myself and it seems to be a very consistent and accurate powder. Keep up the good work and I look forward to more reports!

RB

One good shot doesn't make a match but one bad shot dang sure can ruin a match!

- Okawbow

- Ten ring

Offline

Offline - From: Southern Illinois

- Registered: 11/04/2015

- Posts: 123

Re: The quest for the short string

I had a few minutes this morning to try out .475 molded balls, weighed to 1/2 grain, and weighed powder charges. The load was 100 grains Old Eynsford, with a .019 teflon patch. There was a 13 mph wind, but I shot between gusts. Just a 5 shot group. but I think I'm on the right track. IMG_0316 by okawbow, on Flickr

IMG_0316 by okawbow, on Flickr

- •

- crankshaft

- Eight ring

Offline

Offline - Registered: 2/12/2015

- Posts: 53

Re: The quest for the short string

oooooohhhhh....Is that 60 yd? ?.

Good!

slacker

- Okawbow

- Ten ring

Offline

Offline - From: Southern Illinois

- Registered: 11/04/2015

- Posts: 123

Re: The quest for the short string

Shot off the chunk at 60, but I used a sandbag under the butt, so I took out as much of me as possible.

Just looking for the best load for now. I'll practice my hold once I get the rifle shooting 1 hole.

- •

- barton

- X ring

Offline

Offline - From: Central Kentucky

- Registered: 8/12/2014

- Posts: 165

Re: The quest for the short string

Nice progress. You're doing your due diligence and will reap the rewards at matches!

I need to do some of this with my "new" .50. I can never seem to get time, but the times I've shot it, I know it is still cutting patches a little and throwing shots.

- crankshaft

- Eight ring

Offline

Offline - Registered: 2/12/2015

- Posts: 53

Re: The quest for the short string

Did you change one factor at a time and check the change ??? So, with Teflon patches.....what are your conclusions? ? ?

slacker

- Okawbow

- Ten ring

Offline

Offline - From: Southern Illinois

- Registered: 11/04/2015

- Posts: 123

Re: The quest for the short string

I found, after trying 3 different powders, and 2F and 3 F in each, that powder type only mattered slightly in my rifle. Amount of the powder charge made much more difference.

Changing to a proper thickness Teflon patch made the groups more consistant than any other variable. However, the Teflon patches required careful cleaning between shots.

Re cutting the barrel crown also made the groups tighter. Since I made this rifle with a used barrel, it's possible the crown was damaged or worn.

Finding a mold, and molding bullets instead of using the swagged bullets, also helped. Also, getting an accurate scale and weighing bullets and powder to eliminate another variable helped reduce fliers.

Changing my front sight to a pin and tube, along with using a spotter with the correct size center dot and black circle to fit the pin and tube, helped me aim more consistently.

All these things combine to shrink my groups from about 3" to less than 1" at 60 yards.

I'll still try and fine tune my powder charge and also work out a load with Swiss powder to see if that works better than Old Eynsford. Finally, I'll have to work on my hold and follow through to shoot those small groups in competition as well as practice.

- •

- rhbrink

- Target master

Offline

Offline - From: Pleasant Hill, MO

- Registered: 7/26/2014

- Posts: 285

Re: The quest for the short string

Good work! This shows what work with patches, ball size, powder brand, and powder charges can accomplish.

RB

One good shot doesn't make a match but one bad shot dang sure can ruin a match!

- barton

- X ring

Offline

Offline - From: Central Kentucky

- Registered: 8/12/2014

- Posts: 165

Re: The quest for the short string

Sometimes teflon seems to work better just because it is tougher. Might be interesting to see how denim compares after the barrel work.

I found teflon made a minor improvement over denim and canvas in my .40, but needed 3x as much cleaning between shots, so I didn't follow up and use Teflon. I then found that denim worked pretty much the same as teflon as long as I was very consistent with amount of lube on patch. I guess teflon is inherently easier to stay consistent, but I was concerned it would build up over time and require different cleaning technique.

Also, teflon in a flintlock just seems wrong, though I may use it ![]() .

.

- Don Steele

- Ten ring

Offline

Offline - From: Sebastian, FL

- Registered: 8/09/2014

- Posts: 138

Re: The quest for the short string

It's been my experience that sight choice is an extremely critical factor when you are trying for the smallest one-hole group. A lot of good loads will get you a one hole group from a rest. Getting that one hole as small as possible requires matching your spotter target design, your eyesight, and the choice of front/rear sights on your rifle.

I'm using a Lyman Globe front, post and dot reticle. The rear sight is an open blade that I modified with JB weld to fill in the oversized notch, then re-cut a new minimal v-notch. My best spotter design is similar to yours, but I added a white band across the bottom that just touches the Chartreuse circle I'm using in the center of the black. The white band allows me to see my sights better when I'm aligning them and drawing the "dot" in my front sight over the circle on the target.

Ain't this fun..??!!!

- rhbrink

- Target master

Offline

Offline - From: Pleasant Hill, MO

- Registered: 7/26/2014

- Posts: 285

Re: The quest for the short string

This IS FUN! But the acid test comes when the match if ON! And ten shot groups, I don't know how many great one hole groups that I have shot when nobody is around and I have the range to my self, take all the time in the world and make every shot perfect. But when shooting a match with lots of people around, added distractions, range officer hollering out commands and a time clock going off in your head things change fast and usually not for the better. But that is the challenge of it after you do your home work as Okawbow is doing.

I read above where some people are getting good results with denim but for myself that has never happened and I don't really find any build up of Teflon as reported and some local guys say that they have a Teflon build up too? Maybe I clean better than most? I don't but it works for me. I have had really good success with the Army Canvas Duck and a ballistol and water mix applied and let dry almost as good as Teflon, mighty close but I would still bet on Teflon on a real important match.

RB

One good shot doesn't make a match but one bad shot dang sure can ruin a match!

- Longone

- Seven ring

Offline

Offline - From: CT.

- Registered: 10/11/2014

- Posts: 38

Re: The quest for the short string

If this is dragging the thread in a wrong direction please feel free to move it else where. My question is folks talk about Balistol and water mix and letting it dry before shooting, has anyone use it wet, as in wetting the patch at the time of loading?

Longone

- Okawbow

- Ten ring

Offline

Offline - From: Southern Illinois

- Registered: 11/04/2015

- Posts: 123

Re: The quest for the short string

I use a 6-1 water to balistol mix, wet on heavy denim for most of my offhand matches. I don't clean between shots on woods walks or most offhand matches, and the wet patches go down good.

I don't make them soppy wet, and try and get them the same each time. Sometimes I pre wet a strip, and use it through out the match, so all patches have the same amount of mix on them.

The thick, wet patches seem to work best in my deep groove barrels. I've used them in my chunk gun, and sometimes have 1 hole groups for several shots, but always seem to get fliers that ruin the string.

- •

- Longone

- Seven ring

Offline

Offline - From: CT.

- Registered: 10/11/2014

- Posts: 38

Re: The quest for the short string

Well that answers that question, one thing I can say for sure about fliers is they don't just go away or fix themselves. There is a cause and until you can identify that cause you will have them. Thanks for the reply.

Longone

- rhbrink

- Target master

Offline

Offline - From: Pleasant Hill, MO

- Registered: 7/26/2014

- Posts: 285

Re: The quest for the short string

I have used ballistol and water wet and it shoots OK maybe for offhand shooting but I have never been able to make it shoot as well and the dry patch or Teflon.

RB

One good shot doesn't make a match but one bad shot dang sure can ruin a match!

- Longone

- Seven ring

Offline

Offline - From: CT.

- Registered: 10/11/2014

- Posts: 38

Re: The quest for the short string

I suspect that the lubricity of any lube will have a "sweet" spot velocity wise as well as a pressure level that is built (before or as) when the ball moves down the barrel. That coupled with the harmonics of the barrel will show up on target. Sometime this season I am hoping to bring the chronograph to do some testing, it might be a waste of time as I figure the patch will be the fly in the ointment. Barrel condition between shots I am learning is a BIG factor, being able to maintain that is pretty elusive to me at least.

Longone

- dickh

- Ten ring

Offline

Offline - From: East Central Indiana

- Registered: 5/11/2014

- Posts: 88

Re: The quest for the short string

Fred Stutzenberger had an article in the May/June 2011 issue of Muzzleloader called taming of the sprue.

He said got tighter groups by rolling balls between two thick glass plates to roll the sprue back into the body of

the ball. He called it tumbling the balls the pictures with the article showed tighter groups with the tumbled balls.

I rolled some .395 balls for my 40 cal. rifle and used them at the Indiana state table shoot my group was tighter

don't know if it was the balls or I was just seeing better that day need to shoot more groups to tell. Any one trying

for better groups give tumbled balls a try report back and tell if it helped.

Dick

- crankshaft

- Eight ring

Offline

Offline - Registered: 2/12/2015

- Posts: 53

Re: The quest for the short string

I wonder, why glass ? Wouldn't rolling between metal work ? I would probably break glass.

slacker

- dickh

- Ten ring

Offline

Offline - From: East Central Indiana

- Registered: 5/11/2014

- Posts: 88

Re: The quest for the short string

I would think metal would work as well as glass but the glass might be smoother.

Dick

- Don Steele

- Ten ring

Offline

Offline - From: Sebastian, FL

- Registered: 8/09/2014

- Posts: 138

Re: The quest for the short string

I've read those kind of reports. One fellow said he put his freshly cast balls in a metal box in the back of his truck and drove around.

He said that eventually, the sprues disappeared. My concern would be that the extra metal which had compromised the sprue is still there, just sort of smeared over the surface. I can't imagine that would create an issue for offhand shooting, but might..just might show up when shooting off a rest.

I'm probably overthinking this, but I'm one of those people who weight grade my balls to within +\_ 0.1 gn. For the 40, and 0.5 for the 50.

Muzzle loading target shooters Forums

Muzzle loading target shooters Forums  http://prwarner.wix.com/mlts-masters Email mlts.masters@gmail.com

http://prwarner.wix.com/mlts-masters Email mlts.masters@gmail.com

1 of 1

1 of 1